Supporter System

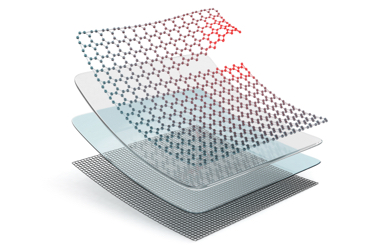

A cordless carrier-type capable of maintaining adsorption without a power supply unit, which transcends the concept of the conventional electrostatic chuck.

This can revolutionize the manufacturing process of semiconductors

Supporter is an electrostatic chuck formed by sandwiching a special material between both sides of a durable base material. The Supporter is used as a jig (carrier) to support a wafer in a semiconductor manufacturing process. In addition to the characteristics of Tsukuba Seiko's existing electrostatic chucks, the Supporter has the characteristic of maintaining adsorption power even when separated from the power supply unit.

Once an electric field is applied using the power supply unit, adsorption force is maintained semi-permanently. To separate the object from the "Supporter", simply use the power supply unit again to release the electric field to separate the "Supporter" from the work.