What is an electrostatic chuck?

A “chuck” is a tool that is used widely around the world and is a tool for holding work objects or cutting tools in place. For example, typical examples of a chuck include tools that clamp a work in place like a vice or a drill chuck that fixes drill bits for cutting onto a processing machine. An electrostatic chuck is a tool that achieves adsorption through Coulomb force generated between the work (object for machining) and electrodes to which a voltage has been applied. An electrostatic chuck is the same as a vice or a drill chuck in the sense that it is used to hold an object in a fixed position. However, an electrostatic chuck applies adsorption force evenly over a wide area of the work object, providing the optimal features required when you want to fix the position of a delicate and fragile object that cannot be handled by a vice or drill chuck.

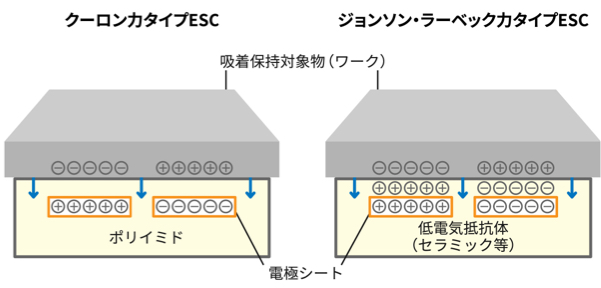

The two operating principles of electrostatic chuck

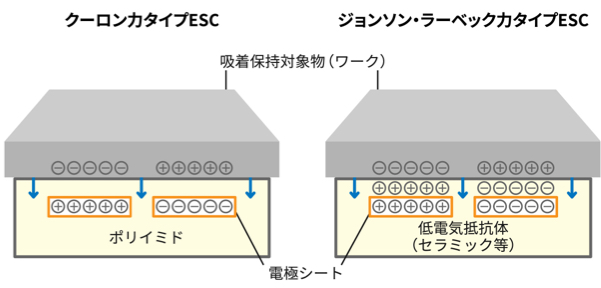

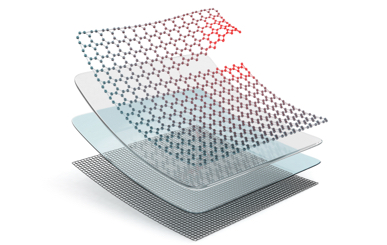

There are two types of adsorption methods for electrostatic chucks: the Coulomb force type, which uses an insulating material as the dielectric, and the Johnsen-Rahbeck force type, which flows a minute current across the small gap between the work and the dielectric to cause charge polarization, resulting in attractive force .

Comparison of chucks based on other operating principles

Adsorption by an electrostatic chuck is based on an electrical force applied evenly over the entire adsorption surface. This provides the benefit of making it difficult to apply physical stress to the work.

As a result, electrostatic chucks are being used in production sites manufacturing advanced electronics as an adsorption-based fixing method for thin, delicate work (semiconductor wafers, glass, metal foil, film).

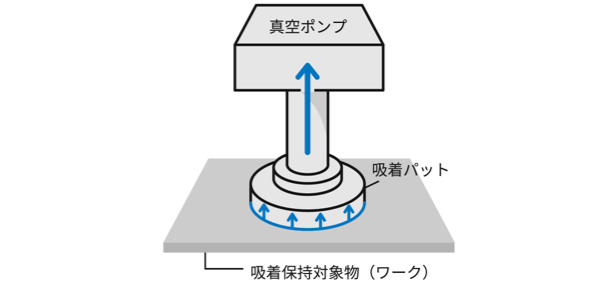

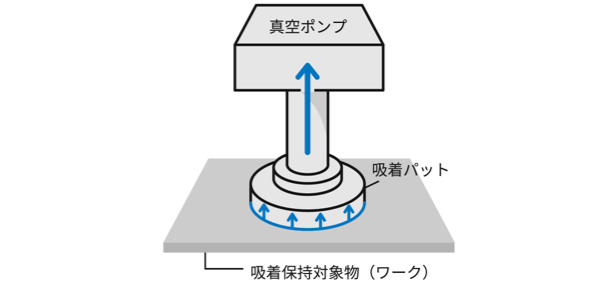

By comparison, mechanical chucks and vacuum chucks widely used in manufacturing plants are widely used in applications such as work movement where delicacy is not required. These types of chucks are selected based on the work characteristics.

Mechanical chucks use a machine to fix work in place so the work is subjected to physical stress, which can result in breakage or warping.

Vacuum chucks fix work in place by creating a vacuum environment. As a result, work cannot be maintained evenly in some cases or can leave adsorption marks on the work, meaning this method can be difficult to apply depending on the work properties.

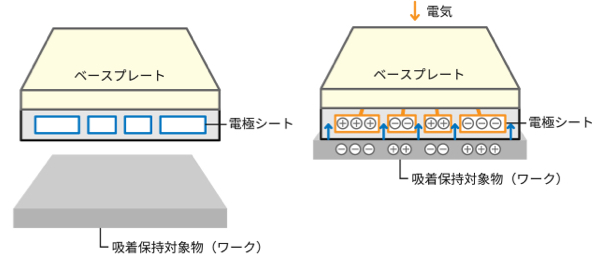

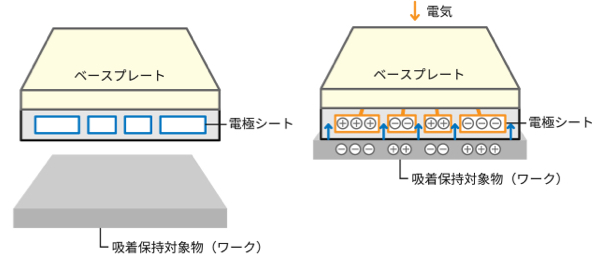

Adsorption principles of Tsukuba Seiko electrostatic chucks

Voltage is applied to the electrostatic chuck’s internal electrodes optimized over many years of R&D to concentrate an electric field around the interface of the work adsorption surface. This electric field separates the positive and negative ions inside the work to drive the positive ions near the negative electrodes and drive the negative ions near the positive electrodes.

Adsorption results from a strong Coulomb force generated between the positive ions and the negative electrodes and between the negative ions and the positive electrodes. No electrical load is applied to the work and the work is not subject to electrostatic damage because this process only polarizes ions that were already present.